RTD vs Thermocouple For Temperature Measurements

A RTD (Resistance Temperature Detector) and a thermocouple are two of the most commonly used temperature sensors in various industries. They both have their own advantages and disadvantages but are both suitable as a temperature sensor

A thermocouple is cheaper, has a wider temperature range, and is more durable than an RTD. However, it has lower accuracy. On the other hand, an RTD has higher measurement accuracy, and better stability. But it is more expensive and requires a power source.

In this article, we will discuss the advantages and disadvantages of the many factors between RTDs and thermocouples temperature sensors, so you can find the most suitable sensor type for the performance required by your temperature measurement.

Sensor Types

Both RTDs and thermocouples work on the principle of temperature-dependent resistance. However, they use different materials to measure the change in resistance.

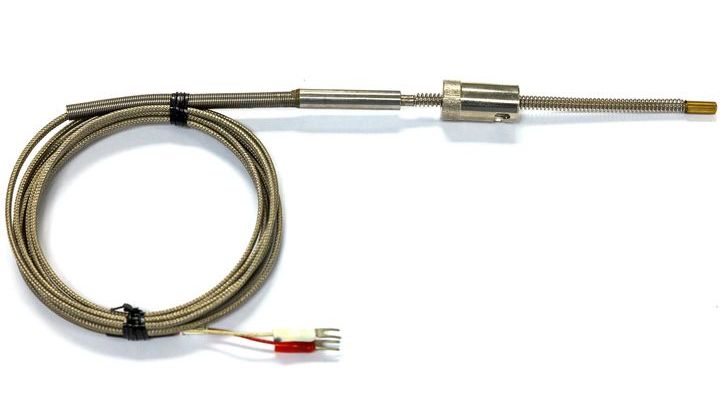

RTD Sensor

Resistance temperature detectors or RTDs are made from metals with a high-temperature coefficient of resistance, such as platinum or nickel. As the temperature increases, the resistance of an RTD also increases proportionally. You can read much more about specifically RTD temperature sensors here.

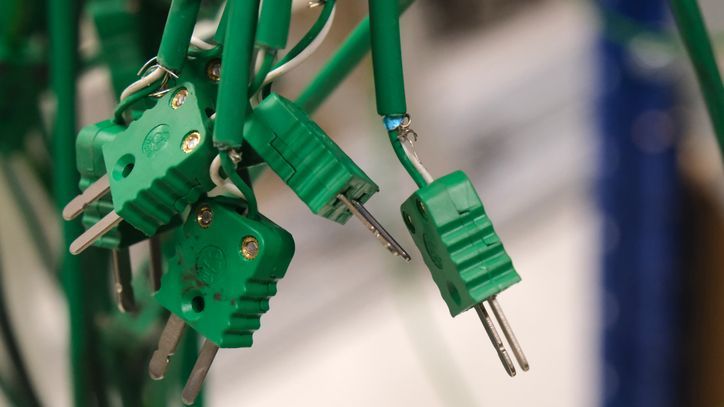

Thermocouple Sensor

Thermocouples consist of two different wires made from dissimilar metals that are joined together at one end. When there is a temperature difference between the two junctions, a voltage is produced due to the Seebeck effect. You can read much more about specific thermocouples here.

There exist many different kinds of thermocouple models, such as Type J, K, T, E and many others. Each type has a different range of temperature measurement and is made from different materials.

Sensor Range

The main difference between an RTD and a thermocouple is their temperature range capabilities. Thermocouples have a wider temperature range compared to RTDs, making them suitable for use in high-temperature applications such as furnaces and engines.

Thermocouples have a measurement range from -200°C to +1750°C, while RTDs typically have a range from -200°C to +850°C.

On the other hand, RTDs are more suitable for low-to-medium temperature ranges due to their higher accuracy and stability.

Sensor Accuracy

The biggest advantage of RTD vs thermocouple sensors is that RTD sensors have a high accuracy compared to thermocouples. The resistance-temperature relationship in an RTD is highly linear, making it more precise and repeatable. RTDs can have accuracies of up to +/- 0.1°C.

On the other hand, thermocouples cannot match RTD accuracy due to non-linearity in their measurement range which affects sensor accuracy. They also require calibration to maintain their accuracy. Thermocouples have accuracies of approximately +/- 1°C.

RTD accuracy can vary depending on the model, and cost this is defined by the class of the RTD sensor, with Class A being the most accurate and expensive, while Class B is less precise but more affordable.

Sensor Reliability

Thermocouples are highly regarded for their exceptional ruggedness and unwavering reliable output even in the harshest of environments. Designed to withstand not only high temperatures but also intense vibrations and corrosive atmospheres, thermocouples truly excel in demanding conditions.

On the other hand, while RTDs may be comparatively more fragile and prone to damage from extreme temperatures or mechanical stress, they should not be overlooked.

With proper installation and meticulous care, an RTD can still exhibit an impressive lifespan, allowing for accurate temperature measurements and reliable performance over an extended period of time.

Cost Comparison

Most thermocouples are generally cheaper compared to RTDs higher device price. They require less material and simpler construction, meaning a cheaper manufacturing process. Their price range is typically $10-50 per unit.

RTDs, on the other hand, are more expensive due to their complex construction and use of costly materials such as platinum. Their price range is typically $100-$500 per unit.

This is of course dependent on the thermocouple type and RTD sensor.

Additionally, thermocouples do not require a power source or special circuitry for operation, further reducing the overall cost.

However, when it comes to long-term use and maintenance costs, RTDs may be a better option due to their higher accuracy and stability. Thermocouple readings tend to drift over time, increasing the need for frequent calibration or replacement.

Power Requirements

One of the major advantages of thermocouples vs RTDs is that they do not require a power source for operation. As mentioned before, thermocouples generate a voltage due to the Seebeck effect, eliminating the need for external power.

RTDs, on the other hand, require an external power source to measure resistance changes. This increases the overall complexity and cost of both sensors, but also the measurement system needed.

Response Time

In terms of response time, thermocouples are known to have a faster response compared to RTDs. As they measure temperature through voltage changes caused by the Seebeck effect, they can quickly respond to temperature changes.

On the other hand, RTDs require more time to reach thermal equilibrium and provide an accurate measurement due to their high mass and slow heat transfer rate. This can be a disadvantage in applications where quick temperature changes occur.

Environmental Impact

Thermocouples and RTDs also differ in their environmental impact and sustainability factors. Thermocouples, typically made from common metals, can often be more easily recycled than the pure platinum or nickel used in RTDs. This can be a significant consideration for industries looking to reduce their ecological footprint.

Installation

Installation complexity and system compatibility are further factors that distinguish thermocouples from RTDs. Thermocouples can be integrated into a wider range of existing systems with minimal effort, largely due to their simplicity and passive nature.

RTD installation might necessitate more elaborate setups, including specific wiring configurations (two-wire, three-wire, four-wire) and a constant power supply, which may not be seamlessly compatible with all systems.

Hardware and Software Compatability

Thermocouples are also known for their compatibility with a wide range of instrumentation and control systems, making them more versatile in terms of system integration.

On the other hand, RTDs require specialized measurement circuits and equipment to accurately read temperature changes, limiting their compatibility with certain systems.

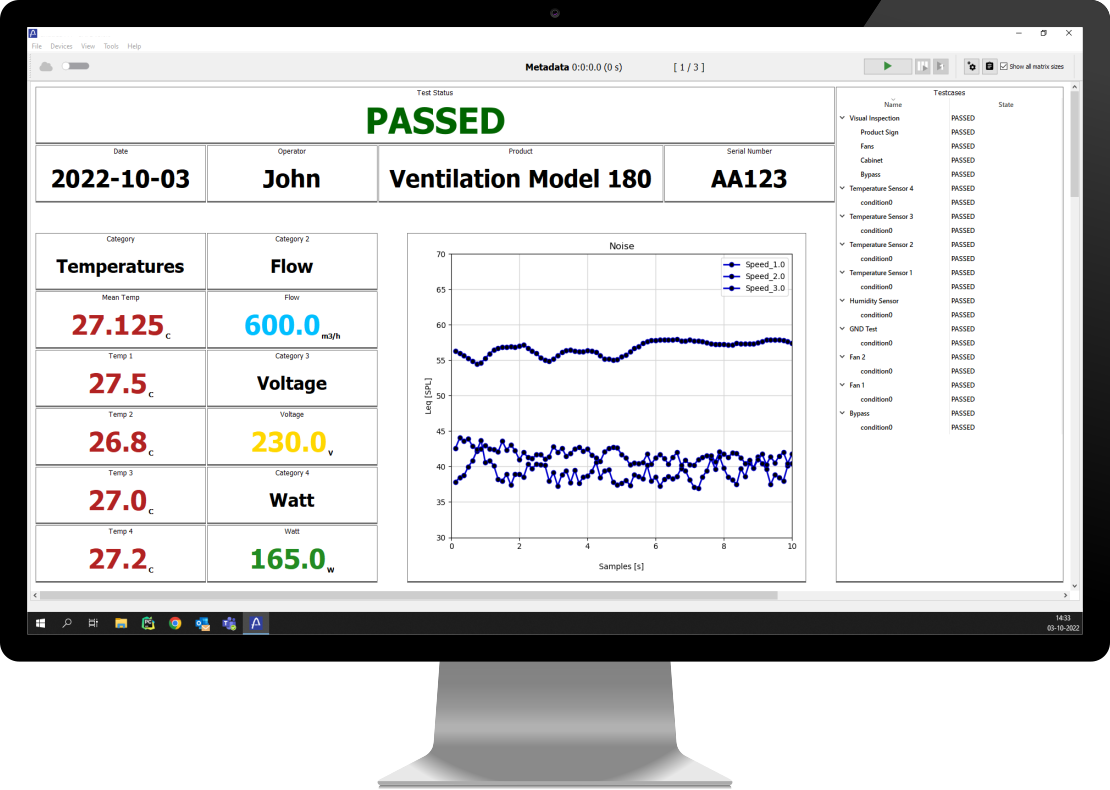

We have made a data logging software that can be used with systems for both RTDs and thermocouples called SAFE which you can download and try here

What Type of Temperature Sensor Should You Choose?

In conclusion, the choice between RTD and thermocouple sensors should be made after careful consideration of the specific application requirements.

Choose RTDs when high accuracy, stability, and reliable performance in low-to-medium temperature ranges are paramount. They are better suited for environments where the temperature conditions are stable and require precise and repeatable measurements.

Alternatively, thermocouples are ideal for high-temperature applications, rapid response needs, and situations where installations must endure rugged or harsh conditions. Their cost-effectiveness and passive nature without the need for an external power source make them well-suited for a wide range of industrial scenarios.

As with any technological selection, factors like cost, installation complexity, power requirements, accuracy, reliability, and environmental impact should be thoroughly evaluated to make the most appropriate choice for your temperature sensor needs.

But in this article, you have hopefully gotten a bit of an overview on how to choose between RTDs vs thermocouples.