This website use cookies to ensure you get the best experience on our website

Customer Story

KVM-Genvex

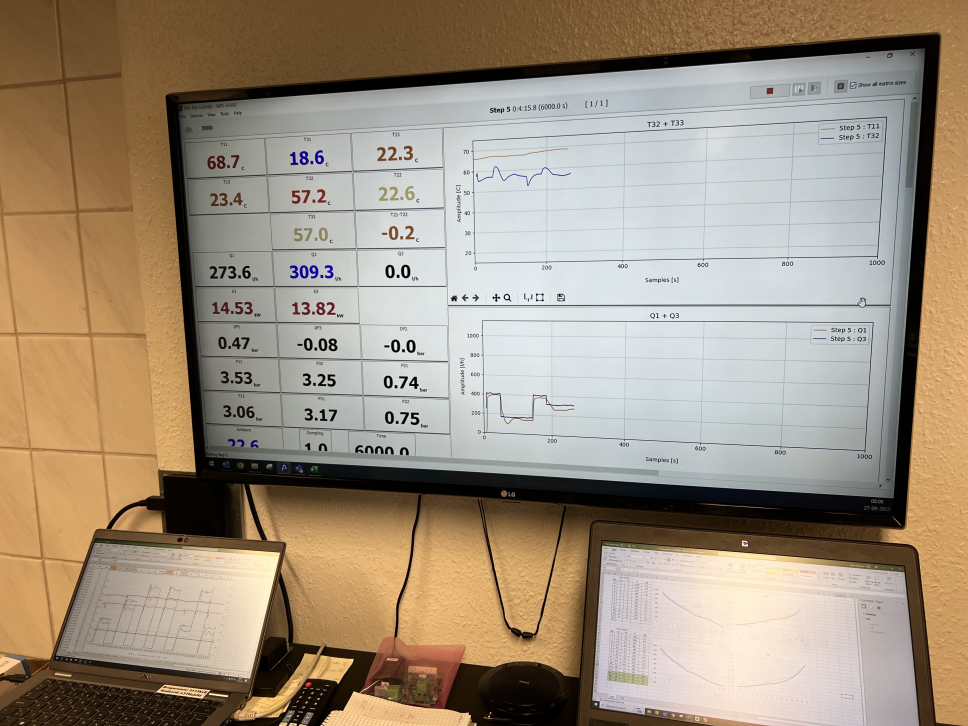

Encida enables KVM Genvex to automate R&D testing to improve data acquisition, validation and comparison making it easier for KVM Genvex to get the data needed to improve their products.

- A more precise way to validate and compare test data

- Easier reproduction of test with tap profiles

- Elimination of the work involved in cutting and copying data after a test

Automating R&D Testing of District Heating Controllers With Dynamic Test Profiles

"I can validate data more precisely and compare it with the tests I have made earlier and the test I just made. There is a certain tap profile and then I can find data that I have made earlier this year, which I know has been made in the same way. It gives a sharper comparison," says Viktor from KVM-Genvex.

At KVM-Genvex, a leading manufacturer of energy-efficient ventilation systems, they have great success in automating tests with Encida's test software SAFE to streamline lengthy tests and obtain better test data for the development of new products. We had a chat with Viktor, Design Engineer at KVM-Genvex, about his experiences.

Established in 1978, Genvex is committed to improving and optimizing their ventilation systems. They are relentless in their pursuit of developing sustainable, energy-efficient, and indoor climate-focused products from their factory in Haderslev.

When Genvex develops new products or a new control, there is always a large testing process where Genvex must perform functional tests and other standard tests to benchmark their performance. This used to be done manually where Viktor sat with a clock and switched valves at specific times and a simple data logger. With Encida's help, Viktor's remote heating test was automated, resulting in much more precise data.

"So earlier it was not so easy. Then I had to sit with a clock and switch some valves to get roughly the same data. Now it is more precise and more automated, and I can simultaneously collect prototypes while the test can work itself," says Viktor.

Another great advantage of using Encida's software SAFE is that test data is readily available. "I just started the test and afterwards it saves itself after the time it should be. I don't have to cut any data or anything. I test according to certain profiles that have certain periods and afterwards I automatically get graphs that come immediately," explains Viktor.

By using Encida's software SAFE, engineers and technicians have a simple way where they can create and customize their own tests. "The structure that I can make and quickly adapt and add some graphs and parameters. We have had several customer visits right now, like software engineers who were also quite impressed with what it can do. So we can do more at the same time right now, because it is more intuitive and understandable to do automation," explains Viktor.

When asked what the best thing about Encida's software SAFE is, Viktor replies, "The opportunity for flexibility and doing what you want." This does not mean that Viktor believes there is no room for improvement in SAFE. Therefore, we always continue with the development of the SAFE platform, so skilled engineers like Viktor can keep benefiting from its capabilities.

At Encida, we are proud to have helped KVM-Genvex automate many of their tests and be a small contribution in their mission to develop products that are energy-efficient, sustainable, and provide a good indoor climate. We look forward to continuing the good cooperation.