Modbus TCP vs Modbus RTU: What Are the Differences?

Modbus RTU and Modbus TCP are two types of Modbus communication protocols, both used in industrial automation, industrial devices, programmable logic controllers (PLCs), and SCADA systems but vary in their communication methods and applicability. The fundamental difference lies in how they are transmitting data with different protocols.

Modbus RTU

Modbus RTU protocol, or Remote Terminal Unit, implements a serial communication protocol over RS-485. It offers the following benefits:

- Packs data more densely, optimizing bandwidth usage.

- Utilizes CRC (Cyclic Redundancy Check Checksum) for data integrity verification.

- Highly reliable for industrial applications.

Modbus RTU is usually connected by a physical wire, and the communication protocol is straightforward with minimal overhead. Connecting the serial lines can however be confusing and has a limiting number of 32 Modbus RTU devices that can be connected to the network in a daisy chain.

Modbus TCP

Modbus TCP IP, or Transmission Control Protocol, leverages the ubiquity and high-speed capabilities of a modern Ethernet network. It wraps the standard Modbus frames in a TCP/IP wrapper, making it a suitable option for high-level or remote applications. Some key features of Modbus TCP IP include:

- Faster data transfer rates over ethernet communication.

- Can handle more devices, up to 255 units on a single network.

- Easy installation and configuration due to the use of standard Ethernet hardware.

Modbus TCP IP is versatile, as it allows both wired and wireless connections. It also provides better scalability compared to Modbus RTU, making it suitable for larger industrial networks.

Comparing Modbus Protocols

When comparing Modbus RTU and Modbus TCP, it's evident that each has distinct strengths and weaknesses for various applications. To fully grasp their use cases, let's delve into their characteristics, properties, and real-life performance. The following sections will highlight their differences and similarities.

The Similarity Between Protocols

Both Modbus RTU and Modbus TCP IP have the same data model, meaning they can exchange the same data types.

- Modbus register types are used to exchange data between devices, such as coils, discrete inputs, input registers, and holding registers are identical.

- The function codes used by both protocols are identical in syntax.

The Differences Between Protocols

From the descriptions above, we can highlight a few key differences between Modbus RTU and Modbus TCP:

- Modbus RTU has a baud rate setting which affects data transfer rates, whereas Modbus TCP has a fixed rate determined by the ethernet network.

- Modbus TCP IP has an IP address for each device, whereas Modbus RTU uses a node number assigned by the master device.

Choosing the Right Modbus Protocol

While both protocols serve the same ultimate goal of facilitating communication between Modbus devices in a Modbus network, their unique characteristics make them more or less suitable depending on the specific requirements of the application.

Factors to Consider

When choosing between Modbus RTU and Modbus TCP, there are several factors that you should consider:

- Speed: Modbus TCP offers faster data transfer rates compared to Modbus RTU, making it suitable for applications that require high-speed communication.

- Distance: Modbus RTU is limited by the distance of the physical wire used, while Modbus TCP can cover longer distances using ethernet cables or wireless connections.

- Network size: If you have a large number of devices in your network, Modbus TCP would be a better option due to its higher scalability. However, for smaller networks with fewer devices, Modbus RTU may suffice.

- Cost: Modbus RTU is generally less expensive to implement compared to Modbus TCP, as it does not require additional hardware such as ethernet switches or routers.

- Compatibility: A Modbus device may only support one type of Modbus protocol, so compatibility with your existing devices should also be considered.

Modbus RTU vs. Modbus TCP

- Modbus RTU is ideal for use over RS-485 and offers efficient bandwidth usage and data integrity.

- Modbus TCP is designed for an Ethernet network and is suitable for high-level or remote applications. It also allows for easier installation and configuration.

- Modbus RTU is more common in smaller industrial networks, while Modbus TCP is typically used in larger and more complex systems.

- Modbus RTU is limited in terms of scalability, while Modbus TCP can handle a larger number of devices on a single network.

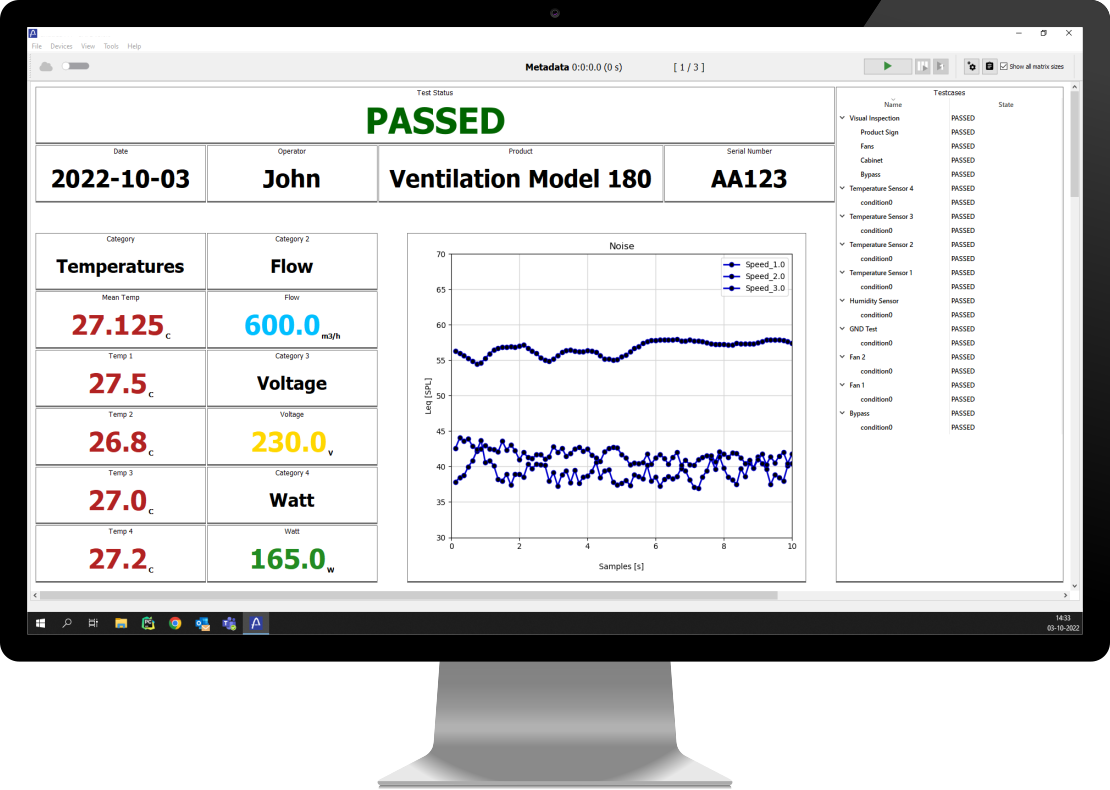

Try Our Modbus Data Acquisition Software

Need software for Modbus data logging, then we have a great tool called SAFE. Download it and try it for free now. Log data from any device and analyze data in real time. Build awesome dashboards like the one below and become a Modbus expert.

Conclusion

Modbus RTU and Modbus TCP are both widely used communication protocols in industrial automation. While they serve the same purpose, their differences make them more or less suitable for different applications. When choosing between the two, it is essential to consider factors such as speed, distance, network size, cost, and compatibility with existing devices. Ultimately, the right choice will depend on the specific requirements of your industrial automation project. So, whether you are looking for a more cost-effective option or need higher data transfer speeds and scalability, understanding the differences between Modbus RTU and Modbus TCP will help you make the right decision. So, take your time to evaluate your needs and choose the protocol that best fits your industrial automation project for optimal performance and reliability.